In the ever-evolving world of technology, industries are becoming increasingly reliant on sensitive electrical equipment to drive efficient operations. However, amidst this dependency lies an invisible threat that looms over these intricate systems: power surges, also known as "transient over-voltages." These surges pose a substantial risk to the seamless functionality of these systems. As a result, industrial surge protection has emerged as an indispensable component of any comprehensive business strategy.

Power surges are characterized by transient over-voltages that occur over a brief duration, typically ranging from milliseconds to microseconds. The havoc they can wreak on electrical infrastructure is considerable, often leading to costly downtimes and potential safety hazards. These surges are primarily instigated by lightning strikes or switching operations. Yet, their origins can also be attributed to electrostatic discharge, brush fires of large electric machines, power supply fluctuations, ground faults, short circuits, triggered fuses, and the parallel installation of energy and information technology control systems.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Imagine the scenario of a bustling factory, equipped with an array of expensive machinery, suddenly being brought to a standstill due to a power surge resulting from an overloaded transformer or a lightning strike. The ensuing cost of replacing damaged equipment and the detrimental impact on business operations, stemming from missed deadlines, can be catastrophic. This is precisely where industrial surge protection comes into play.

Industrial surge protection devices, referred to as SPDs (Surge Protection Devices), were formerly known as transient voltage surge suppressors (TVSS). These devices are meticulously designed to shield electrical systems and equipment from the adverse effects of surge events. Their mechanism involves the restriction of transient voltages and the redirection of surge currents, thereby serving as a safeguard for machinery and processes in various sectors including manufacturing, telecommunications, control systems, and safety interlock circuits.

An SPD operates in a manner akin to an open circuit during regular usage, maintaining isolation between active conductors and the earth. However, when confronted with an overvoltage incident, the SPD switches into an active state, channeling the current back to its source or ground, effectively functioning as a closed circuit. This prompt response short-circuits and confines the overvoltage to a tolerable level for the connected equipment. Once the surge has been dissipated, the SPD reverts to its initial impedance, reinstating the open circuit configuration.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

A professional approach to lightning and surge protection entails the utilization of SPDs classified according to established standards. Type 1 SPDs, for instance, are adept at discharging partial lightning currents, primarily employing spark gap technology. On the other hand, Type 2 SPDs are engineered to inhibit the propagation of overvoltage within electrical installations, concurrently safeguarding connected equipment. These devices commonly rely on metal oxide varistor (MOV) technology. Type 3 SPDs, with a lower discharge capacity, are strategically positioned to complement Type 2 devices in proximity to sensitive loads.

Undoubtedly, surge protection holds paramount significance in the mining industry due to the extensive reliance on advanced electrical and electronic equipment for multifaceted operations spanning extraction, processing, and transportation. The susceptibility of these operations to power surges, often triggered by lightning strikes or electrical faults, underscores the gravity of implementing comprehensive surge protection measures. The repercussions of equipment damage can be both financially burdensome and operationally disruptive. Mining sites, frequently situated in remote locations, encounter additional vulnerabilities arising from unstable power supplies. By embracing robust surge protection strategies, mining companies can ensure the preservation of costly machinery, seamless operations, and the enhancement of worker safety through the mitigation of potential electrical accidents.

Investing in industrial-grade surge protection undeniably constitutes a prudent decision. Swartz Engineering, a reputable provider in the field, offers an array of industry-leading SPDs. These devices are engineered to reliably redirect surges and currents to the ground, thereby affording protection to both personnel and machinery against potential negative consequences. The spectrum of power surge protection solutions provided caters to diverse applications, ensuring that enterprises can operate securely and without disruption. The investment in surge and lightning protection yields rapid returns by fostering peace of mind and facilitating long-term savings.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Expanding further on the significance of industrial surge protection:

In a world where technology is rapidly advancing, industries are increasingly dependent on intricate electrical systems to optimize their operations. These systems encompass a wide range of equipment, from manufacturing machinery and telecommunications systems to complex control networks. While these advancements bring unprecedented efficiency and productivity, they also bring to light the vulnerabilities posed by power surges.

A power surge, or transient overvoltage, is a brief spike in electrical voltage that can wreak havoc on sensitive electronic devices. This surge can occur for various reasons, including lightning strikes, equipment malfunction, or sudden changes in power distribution. When these surges make their way into an industrial setting, the consequences can be dire. Equipment failures, downtime, and potential safety hazards are just a few of the outcomes that can result from inadequately protected systems.

One of the primary sources of power surges is lightning strikes. As lightning discharges into the ground, it can induce massive electrical currents that travel through power lines and utility grids. Without proper surge protection in place, these currents can infiltrate industrial facilities, damaging or destroying valuable equipment. Similarly, equipment malfunctions, such as short circuits or sudden power fluctuations, can create internal surges that reverberate through the system.

In the context of manufacturing, the reliance on sophisticated machinery is undeniable. Modern factories house a plethora of automated systems that contribute to precision manufacturing and streamlined processes. A power surge can disrupt these delicate systems, leading to misaligned production schedules, costly repairs, and compromised product quality. Furthermore, in industries where safety is paramount, such as oil refineries or chemical plants, a surge-induced system failure could result in catastrophic accidents.

The importance of surge protection becomes even more pronounced when considering the interconnected nature of industrial networks. Many facilities operate using intricate control systems that rely on seamless communication between various components. A power surge in one part of the network can propagate to others, causing a domino effect of failures. This interconnectivity underscores the need for a comprehensive surge protection strategy that covers not only individual pieces of equipment but the entire ecosystem.

Remote locations, often chosen for mining or energy production, are particularly vulnerable to power surges. These areas may experience inconsistent power quality due to their distance from urban power centers. Additionally, the presence of lightning-prone environments in remote regions increases the likelihood of surges. As such, implementing robust surge protection measures is not just a matter of equipment preservation but also of maintaining uninterrupted operations and safeguarding personnel.

Conclusion:

Industrial surge protection is not a luxury but a necessity in today's technology-driven landscape. The potential risks posed by power surges can have far-reaching implications, from financial losses to compromised safety. By investing in reliable surge protection solutions, businesses can fortify their operations against unforeseen disruptions, reduce maintenance costs, and uphold their commitment to employee safety. As industries continue to evolve, the role of surge protection in sustaining seamless operations will remain paramount.

Explore More of Our Products

Whether you need to upgrade your existing surge protection or require new installation, Swartz Engineering can help. Please find out more about our upgrade service or get in touch today.

For more information about these solutions and how Swartz Engineering can assist with your mining and electricity needs, click the links or check out the contact details at the bottom of the page.

Products We Offer

Swartz Engineering strives to provide top-quality products to achieve our customer's needs. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

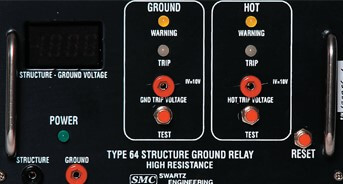

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations

For nearly half a century, we have proudly led the industry in ensuring safety and efficiency. Swartz Engineering is a trusted family-owned company dedicated to providing top-notch power distribution solutions for the electrical industry. Contact us today!