Derating specifications are increasingly used by AC-DC power supply manufacturers to enhance their power ratings. When a power system operates below its headline rating to meet safety and thermal requirements, it is referred to as derating. Temperature and input voltage are two of the most common derated specifications. Due to the growing market pressures on power supply size, power density, and cost, an increasing number of AC/DC power supplies are being released that rely on derated specifications to boost their headline power rating.

The derating information may not be readily apparent and is typically found at the very end of the product's datasheet. This information is often separated from the headline data and may not be included in the catalog or short-form data. In such cases, it's crucial to carefully select the product for your application.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

What Is a Derating Specification?

A derating specification involves a reduction in the output power rating specified for the power supply when it operates at higher temperatures or with a low input voltage. This reduction helps lower the temperature increase of components, extends their lifespan, and ensures that safety-critical isolation parts do not exceed thermal limits. Input voltage and operating temperature are two of the most common derated specifications.

Temperature Derating

Refer to Figure 1 for an example. This derating curve is typically applied to products intended for integration into equipment. The power supply can maintain its full power rating even as the temperature inside the equipment rises. At 70°C, the output power rating is usually reduced to 50%. Some manufacturers also derate their products below 0°C because they can operate at low temperatures.

Output Power Curves Based On Ambient Temperatures

Certain manufacturers have introduced open-frame power supply units that limit the maximum ambient temperatures for full power operation to 40°C. The output power is reduced to 50% when the ambient temperature reaches 60°C. This is due to component temperatures becoming too high at 50°C to sustain full power operation. This practice is driven by component specifications, product safety requirements, and longevity considerations.

This "specmanship," although it may initially seem to offer a higher headline rating, smaller size, or lower cost, actually results in a reduction of up to 25% in the output power when used with end equipment that must operate within an ambient temperature of 40°C. This means that a product with a 100W headline rating is effectively a 75W unit and cannot be compared to other units with the same power rating designed for operation at 50°C.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Input Voltage Derating

Universal input ranges are typically 90-264VAC for products designed to operate worldwide. A product with a universal input should provide its full power across this input range. However, some products may derate their output to operate in areas with AC supply that is prone to brownouts.

It has become more common for manufacturers to specify deratings for input voltages below 100VAC, or even higher than 120VAC. The input derating for 90VAC can be as much as 20%.

This specification derating may make the product appear to have higher power density at a lower price. However, if the product is intended for global use, it will need a higher-power version. A power supply with a 100W headline rating may only be rated as 80W.

As input current increases, input voltage derating can be used to reduce overheating of the bridge rectifier and PFC boost converter. Some losses increase in proportion to the current, but resistive losses such as those seen in EMC chokes increase by the cube of the current.

When the equipment is intended for global sales, it's crucial that the power rating is sufficient at low line voltages. Overriding the derating curves can lead to reliability and lifespan problems.

Combining thermal and line derating results in a 100W power supply rated at 40°C being reduced to 60W when used in an environment of 50°C, with a 90VAC line voltage. This product should not be compared with those that offer a power rating of 100W across the entire input range, but rather to a product rated at 60W.

Derating also applies to the entire final system. To ensure reliability and long-term lifespan, components can be specified to 80% of their rated power. Failure to consider derating curves can negatively impact reliability and lifespan.

The power supply continues to function even when the product specification calls for derating under certain conditions of line voltage and ambient temperatures. Using the product outside the derating curves can significantly affect its reliability, lifespan, and safety.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Conclusion

Understanding power supply derating specifications is crucial for both power supply manufacturers and the engineers and designers who rely on these components for their projects. Derating plays a pivotal role in ensuring the reliability, safety, and longevity of power systems in a wide range of applications.

Manufacturers are increasingly incorporating derating specifications to optimize the performance of their AC-DC power supplies. By doing so, they not only meet safety and thermal requirements but also enhance their power ratings. While these derating specifications may not always be prominently displayed, they are vital for selecting the right product for a given application.

Temperature and input voltage are two common factors affecting derated specifications. Manufacturers use temperature derating curves to maintain safety and component integrity within specified temperature ranges. Input voltage derating, on the other hand, ensures that power supplies can adapt to various line voltage conditions.

It's important to note that disregarding derating curves and operating a product beyond its specified limits can lead to reduced reliability, shorter lifespans, and potential safety risks. When designing systems intended for global use or challenging environmental conditions, it is essential to consider derating as a critical factor in component selection and performance assessment.

In a competitive market where size, power density, and cost are paramount, derating specifications are not merely a footnote; they are a key aspect of ensuring that power supplies operate effectively and safely in the real-world conditions they were designed for. Engineers, designers, and manufacturers must collaborate closely to make informed decisions and deliver high-quality power solutions that meet the demands of modern applications.

Our Expert Services

Swartz Engineering provides top-quality products to meet our customers' needs. We also make sure our products work reliably and safely. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

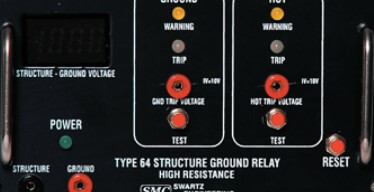

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations