Pressure transducers are essential pieces of equipment in the mining engineering industry. They help measure, monitor, and control pressure levels at various points in a system. Without accurate data from these components, it cannot be easy to ensure that operations run smoothly and safely. Unfortunately, pressure transducers can fail or malfunction for various reasons, leading to costly and time-consuming repairs or replacements.

Pressure transducers are essential pieces of equipment in the mining engineering industry. They help measure, monitor, and control pressure levels at various points in a system. Without accurate data from these components, it cannot be easy to ensure that operations run smoothly and safely. Unfortunately, pressure transducers can fail or malfunction for various reasons, leading to costly and time-consuming repairs or replacements.

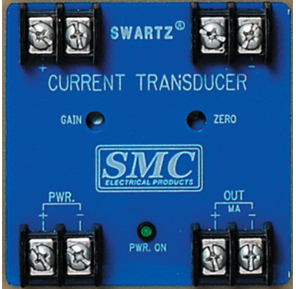

Fortunately, as long as the issue is identified quickly, most common pressure transducer problems can be resolved relatively soon with preventive maintenance procedures or minor adjustments. Here at Swartz Engineering, we understand the importance of having reliable pressure transducers in your systems and have developed some helpful tips to identify when potential issues may arise.

Problems of a Bad Transducer

One common problem with pressure transducers is incorrect calibration. This means that readings from the device don't accurately reflect what's happening in the system or process it is measuring. A few signs of incorrect calibration include a gradually increasing or decreasing reading over time, inaccurate readings at specific points during operation, or erratic readings compared to previous measurements. To address this issue, technicians should regularly check for any signs of wear and tear on components like strain gages or cables. They should also inspect wiring diagrams for errors and replace worn connectors if necessary. Additionally, they should ensure that all wiring connections are tight and secure before running a thorough calibration procedure on the pressure transducer.

Another frequent issue with these devices is electrical interference from other pieces of equipment in close proximity to them. This could lead to inaccurate readings due to electrical "noise" affecting the signal sent by the device. Signs of this type of interference include an unusually high level of variation between successive readings even when conditions remain constant and sudden changes in measurement values without any logical explanation behind them. To prevent interference with your pressure transducer's signal, you must ensure it isn't placed too close (within six feet) to other electrical devices, such as fans or motors, which create more vital electromagnetic fields than stationary ones like computers do. Additionally, using twisted shielded cables can help protect the device from any external noise caused by other equipment within its vicinity.

The last common issue we see from our customers involves mechanical failure due to wear or corrosion on parts such as diaphragms or bellows within the system itself, which may lead to a faulty signal from your pressure transmitter. Signs indicating an underlying mechanical malfunction include sudden drops in measured values where no other anomaly has been detected beforehand and discrepancies between different types of readings even after recalibration procedures have been completed successfully. To tackle this problem effectively, you must first identify points within your system where excessive force might be applied, which could damage specific components over time, before replacing obsolete parts with new ones accordingly. Furthermore, proper precautions should be taken while installing new fittings so that they cannot rust easily over time due to their exposure to corrosive materials used while drilling into particular subsurface strata.

Contact Us Today

At Swartz Engineering, understanding these problems is critical to avoiding costly downtime due to faulty measurements from damaged sensors. So, stay ahead of any potential issues by following our best practices today! Call us to learn more.

Products We Offer

Swartz Engineering strives to provide top-quality products to achieve our customer's needs. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations