In this article, we will take a look at insulated overlap and uninsulated overlap, which are overhead equipment used in electric traction systems.

What is Overhead Equipment?

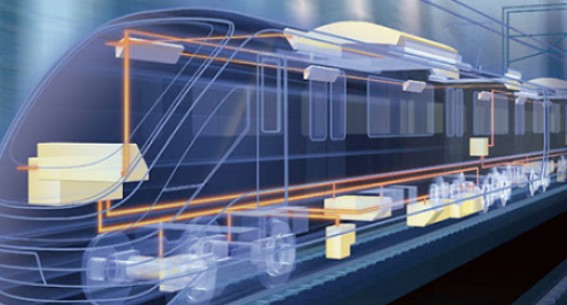

Overhead Equipment (OHE) in electric traction systems is used for transmitting electrical energy to electric locomotives, trolleybuses, trams, and other electric traction systems.

As in any electrical circuit, series and parallel connections are made by twisting cables together, using junction boxes, soldering, brazing, etc. However, in the case of overhead conductor wire (or catenary wire), the use of this equipment is not possible. Therefore, the arrangement employed for the same purpose in the overhead equipment is called an overlap.

Thus, the arrangement in which two sets of contact wires run together in parallel for a short distance without any mechanical or electrical connectivity but provide smooth movement of the pantograph over it is known as an overlap in OHE.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

The Distance Between The Overlaps Is Restricted Because Of The Following Reasons:

1. In order to avoid the difficulties encountered in handling and transportation of conductor due to the limited size of the conductor and weight of the drum on which the conductor is rolled.

2. The need for isolation of portions of OHE that are affected by faults for effective operation and easy maintenance. Hence, it makes it necessary that the overlaps are provided at lesser intervals.

3. When swiveling types of bracket assemblies are used, there is friction between components. This makes it difficult to maintain uniform tension in the conductors if the length of the OHE between the anti-creep and the regulating equipment is long.

Therefore, the length of the regulated OHE never exceeds 1.5 km.

Types of Overlap in OHE

Uninsulated Overlap

When OHE is made continuous, long lengths of it would be affected wherever there is a fault or damage, and the rectification of damage may need a long time. Therefore, it is essential to divide the length of the elementary section into a large number of sub-elementary sections, and each sub-elementary section is separated from its adjacent one by some means which is known as an uninsulated overlap.

Therefore, when two contact wires belonging to two adjacent sub-elementary sections run parallel to each other for at least one span and are electrically connected to each other either by means of a jumper, it is known as an uninsulated overlap.

In the uninsulated overlap, the contact wires cannot be of indefinite length, and the standard length of 1.6 km is used, which is known as one span or one tension length. This standard length is designed by taking into consideration the tension, weight, thermal expansion, etc. Also, the gap provided between two contact wires in the parallel running portion is about 20 cm, which is maintained by the mechanical linkage of the conductors.

In the 25 kV AC traction system, a three-span uninsulated overlap is normally provided on regulated OHE with swiveling-type bracket assemblies as standard overlap.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Insulated Overlap

Insulated overlaps are mainly used for providing isolating facilities required for the operation and maintenance of OHE. The insulated overlaps are also provided at feeding posts, sub-sectioning posts, and booster stations. When two lengths of OHE belong to two adjacent elementary sections, then there will be an insulated overlap span.

In the case of insulated overlap, the following measures are made that are not in the uninsulated overlap −

1. To avoid accidental contact between the contact wires, the gap between them is kept more.

2. In an insulated overlap, the electrical continuity between two sections is maintained by means of jumpers in series with an isolator or interruptor. With this arrangement, a section can be made dead, and maintenance work can be carried out on the other equipment away from the overlap.

3. The anchoring portion of the catenary and contact wire is separated from the rest of the portion by means of insulators provided at a distance of 2.5 km from the supports and within the overlap span. The tail ends of the anchoring OHE are connected to the other nearby equipment to prevent it from attaining another potential.

Insulated overlaps are also used in the following traction systems:

In DC traction systems, a single-span insulated overlap is used. The lateral distance between the two equipment is kept at 0.3 meters for 1500 volts and 0.4 meters for 3000 volts. This separation is maintained by means of insulated rods clamped onto the wires.

In the case of the 25 kV AC traction system, the lateral separation between two equipment is 0.5 meters, and a three-span insulated overlap is normally provided with swiveling types of bracket assemblies.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Conclusion

Uninsulated overlaps, characterized by parallel contact wires in adjacent sub-elementary sections, serve to mitigate damage and faults by dividing the length of the elementary section. The standardized length and mechanical linkages between conductors in uninsulated overlaps demonstrate careful consideration of tension, weight, and thermal expansion.

Conversely, insulated overlaps play a crucial role in providing isolating facilities for operational and maintenance purposes. The increased gap between contact wires and the inclusion of jumpers with isolators or interrupters facilitates a safer working environment. The separation of anchoring portions using insulators further enhances safety measures, preventing unintended electrical contact.

These insights into the types and functionalities of overlaps contribute to the overall reliability and safety of electric traction systems. As technological advancements continue, the engineering principles behind insulated and uninsulated overlaps underscore the commitment to enhancing the efficiency and sustainability of electric transportation infrastructure.

Our Expert Services

Swartz Engineering provides top-quality products to meet our customers' needs. We also make sure our products work reliably and safely. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations