In industrial rail operations, durability is not optional—it is fundamental. Rail systems across the USA operate under constant stress from heavy loads, continuous movement, and demanding environments. When equipment fails, the consequences extend far beyond repair costs. Downtime, safety risks, and production delays can disrupt entire facilities. For this reason, operators rely on Industrial Railway Supply equipment that is engineered to perform reliably over the long term.

Swartz Engineering addresses this need directly. Based in the USA and serving industrial clients nationwide, the company designs and manufactures railway supply equipment with durability as a core requirement, not a secondary feature. Its solutions are built to withstand real operating conditions, helping industrial rail systems remain safe, efficient, and dependable year after year.

Key Takeaways

- Durable industrial railway equipment reduces downtime, safety risks, and long-term costs.

- Swartz Engineering designs products specifically for demanding industrial rail environments across the USA.

- Material selection and precision manufacturing play a major role in equipment longevity.

- Reliable railway components support safer operations and predictable maintenance planning.

- Investing in quality railway supply equipment improves total lifecycle value.

Why Durability Matters in Industrial Railway Operations

Industrial rail systems support some of the most demanding operations in the country. Steel mills, ports, mining facilities, power plants, and large manufacturing sites all depend on rail infrastructure to move heavy materials efficiently. In these environments, equipment is exposed to vibration, impact loads, weather extremes, and constant use.

When railway components wear out prematurely, the effects are immediate:

- Increased maintenance and emergency repairs

- Unplanned shutdowns that disrupt production schedules

- Higher safety risks for operators and maintenance crews

- Escalating replacement costs over time

Durable Industrial Railway Supply equipment helps prevent these issues by delivering consistent performance under repeated stress. For many operators, durability is what keeps rail systems functioning without constant intervention.

Engineering Equipment for Real-World Conditions

Durability does not happen by chance. At Swartz Engineering, it begins with understanding how equipment is used in actual industrial settings. Designs are based on load requirements, operating cycles, and environmental exposure—not just theoretical specifications.

Products are engineered with reinforced structures and conservative safety margins. This approach helps components maintain integrity even when subjected to heavy loads or continuous operation. Swartz Engineering applies established engineering principles to ensure its equipment performs reliably in the field, not just in controlled environments.

This practical focus allows the company to deliver Industrial Railway Supply solutions that meet the realities of industrial rail use across the USA.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

The Role of Material Selection in Equipment Longevity

Materials are one of the most critical factors in long-term performance. While lower-grade materials may reduce initial costs, they often lead to corrosion, fatigue, and early failure. Over time, these issues result in higher maintenance expenses and reduced reliability.

Swartz Engineering prioritizes high-quality steels and proven alloys selected for strength, fatigue resistance, and corrosion control. Materials are chosen based on the application, whether that involves heavy axle loads, exposure to moisture, or abrasive operating conditions.

By focusing on material quality from the start, Swartz Engineering ensures its railway components maintain performance and structural stability over extended service lives.

Precision Manufacturing and Quality Control

Even the best materials require disciplined manufacturing processes. Swartz Engineering uses precise fabrication methods and strict quality control to ensure consistency across every product.

Key manufacturing practices include:

- Accurate machining to maintain dimensional integrity

- Controlled welding processes to reduce stress points

- Thorough inspections to verify compliance with specifications

This attention to detail minimizes defects and ensures each component performs as intended. For customers, this translates into Industrial Railway Supply equipment that can be installed with confidence and relied upon in demanding operations.

Designed With Safety and Reliability in Mind

Safety and durability are closely connected. Equipment that wears out or fails unexpectedly increases the risk of derailments, misalignment, and structural damage. Swartz Engineering designs its products to remain stable under load and resist loosening or deformation over time.

Strong fastening systems and reinforced designs help maintain proper alignment and load distribution. When railway components perform reliably, they contribute to safer working conditions and reduced operational risk.

For industrial operators, dependable equipment is a critical part of maintaining compliance with safety standards and protecting personnel.

How Does Durable Equipment Support Long-Term Operational Efficiency?

Durability directly influences efficiency by minimizing disruptions and enabling better planning. Long-lasting components allow operators to focus on productivity rather than frequent repairs.

- Longer-lasting components lead to more predictable maintenance schedules.

- Fewer unexpected breakdowns mean reduced operational interruptions.

- Stable systems allow better planning for labor, inventory, and budgeting.

- Swartz Engineering solutions are designed to reduce wear and extend service intervals.

- Investing in quality Industrial Railway Supply equipment can lower total ownership costs through reduced downtime and maintenance demands.

Why Is Swartz Engineering a Trusted Industrial Railway Partner in the USA?

Experience and collaboration are key factors in delivering reliable railway solutions. Swartz Engineering emphasizes understanding real-world operating conditions before recommending equipment.

- The company has a strong practical understanding of industrial rail challenges in the USA.

- Swartz Engineering works closely with customers to assess operating conditions, load requirements, and system constraints.

- This collaborative approach avoids generic, one-size-fits-all products.

- Customers receive fit-for-purpose equipment that integrates smoothly with existing systems.

- The result is durable, reliable components tailored for demanding industrial use.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Built for Today’s Demands and Tomorrow’s Needs

Industrial rail operations continue to evolve, placing greater demands on infrastructure and equipment. Swartz Engineering remains committed to continuous improvement, applying proven engineering practices and disciplined manufacturing to meet future challenges.

By focusing on durability, reliability, and customer needs, the company delivers railway supply equipment designed to support long-term industrial success.

Conclusion

Durability is the backbone of effective industrial rail systems. From engineering design and material selection to manufacturing quality and safety performance, every detail influences long-term results. Swartz Engineering delivers Industrial Railway Supply equipment built for heavy loads, harsh environments, and continuous operation across the USA.

For organizations seeking dependable railway solutions that protect their investment and keep operations running smoothly, Swartz Engineering provides equipment engineered not just to function, but to last.

Frequently Asked Questions

What makes industrial railway equipment durable?

Durable equipment is designed to handle heavy loads, repeated stress, and environmental exposure. Quality materials, reinforced designs, and precise manufacturing all contribute to long service life.

How does Swartz Engineering support customers in the USA?

Swartz Engineering works with industrial clients nationwide, providing engineered railway supply solutions tailored to specific operating conditions and applications.

Why is material quality so important in railway equipment?

High-quality materials resist corrosion, fatigue, and deformation, reducing maintenance needs and extending the life of railway components.

How does durable equipment improve safety?

Reliable components reduce the risk of failures that can lead to derailments, misalignment, or unsafe working conditions.

Is durable railway equipment more cost-effective over time?

Yes. While initial costs may be higher, durable equipment typically lowers total ownership costs through reduced maintenance, fewer replacements, and improved uptime.

Products We Offer

Swartz Engineering strives to provide top-quality products to achieve our customer's needs. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

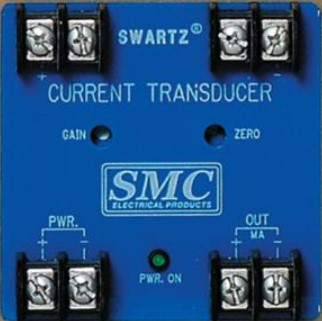

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations

For nearly half a century, we have proudly led the industry in ensuring safety and efficiency. Swartz Engineering is a trusted family-owned company dedicated to providing top-notch power distribution solutions for the electrical industry. Contact us today!