In today’s fast-paced, increasingly connected world, the railway industry is undergoing a significant transformation. This evolution is driven by the need for greater efficiency, safety, and real-time monitoring. At the heart of this change lies a group of small but powerful devices—transducers.

These devices are not new to the field of engineering, but their role in railway automation has grown exponentially. As technology advances, the future of transducers in railway automation looks more promising than ever, reshaping how we perceive, manage, and operate our rail systems.

What Are Transducers and Why Do They Matter?

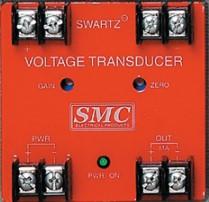

Before we dive into what the future holds, let’s get a clearer picture of what transducers actually are. In simple terms, a transducer is a device that converts one form of energy into another. In the railway context, these devices often convert physical parameters—like speed, force, temperature, or pressure—into electrical signals that can be measured and interpreted.

Why is this important? These signals form the backbone of data-driven automation in railways. They make it possible for rail operators to monitor equipment health, track train movement, detect faults, and ensure that everything runs smoothly and safely.

The Increasing Role of Automation in Railways

Railways around the world are embracing automation like never before. From automated train control systems and predictive maintenance to AI-driven analytics and centralized monitoring, automation is revolutionizing rail operations.

But automation is only as effective as the data it relies on—and that’s where transducers step in. With more trains running faster and networks growing more complex, there’s a rising demand for real-time, reliable data. Transducers act as the sensory organs of railway systems, feeding vital information into automated platforms.

At Swartz Engineering, we see transducers not just as tools but as enablers, making intelligent rail operations possible, scalable, and safe.

Key Areas Where Transducers Make a Difference

1. Track and Infrastructure Monitoring

Cracked rails, temperature variations, or ground vibrations can lead to accidents if left undetected. Transducers installed along the tracks can monitor these conditions continuously. For instance, vibration sensors can detect microfractures before they escalate into major problems.

In the future, we foresee smart transducer systems that can communicate directly with central control centers, triggering alarms or even initiating immediate preventive actions when thresholds are crossed.

2. Train Performance and Condition Monitoring

Modern trains come equipped with dozens of transducers monitoring parameters like speed, fuel consumption, wheel pressure, and brake force. These transducers ensure optimal performance and help prevent failures.

As we move toward fully autonomous train systems, the accuracy and responsiveness of transducers will become even more critical. Imagine a future where AI algorithms use transducer data to instantly adapt train speed, adjust braking power, or reroute traffic—all without human intervention.

3. Passenger Safety and Comfort

It’s not just about the trains—it’s about the people riding them. Transducers also play a vital role in managing passenger-related systems. They can monitor internal temperature, air quality, and even crowd density to ensure maximum comfort and safety.

Advanced optical and ultrasonic transducers are being explored to monitor occupancy levels, helping rail operators manage peak loads more efficiently. In emergencies, transducers could trigger faster evacuation protocols or automatic door operations.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Emerging Trends in Transducers for Railway Automation

The future is already taking shape in labs, pilot projects, and cutting-edge installations. Here are some emerging trends that Swartz Engineering is watching closely:

a) Wireless and IoT Integration

Traditional transducers often rely on wired connections, which can be bulky and hard to maintain. The future points toward wireless transducers equipped with IoT (Internet of Things) connectivity. These smart sensors can be deployed across vast railway networks and managed remotely.

Wireless transducers will simplify installations, reduce maintenance costs, and provide flexible monitoring solutions, especially in remote or harsh environments.

b) Self-Diagnostic Capabilities

Imagine a transducer that not only sends data but can also monitor its own health. That’s the goal of self-diagnostic transducers. These advanced models can detect internal failures, signal calibration issues, and alert technicians before any actual breakdown occurs.

This level of awareness increases reliability and minimizes downtime, crucial for busy railway corridors.

c) Energy Harvesting for Self-Powered Operation

Battery life is a limiting factor in many remote sensing applications. But new research is pushing the envelope on energy-harvesting transducers. These devices can draw power from vibrations, solar energy, or electromagnetic fields around the track to power themselves.

Self-powered transducers could function for years without manual intervention, reducing operational costs and extending monitoring reach.

d) Miniaturization and Multifunctionality

As the demand for compact systems grows, transducers are becoming smaller and more capable. Miniaturized transducers can be embedded directly into wheels, axles, or rail beds without impacting performance.

Moreover, multifunctional transducers are being developed to monitor multiple parameters simultaneously. This means fewer devices are needed to collect the same (or more) information, simplifying infrastructure and reducing costs.

The Human Element Behind Technological Progress

While we marvel at the technical side, it’s important to remember the human aspect of these innovations. Engineers, technicians, and planners work tirelessly to integrate transducer technology in ways that make railway systems smarter and safer.

At Swartz Engineering, we’re proud of the role we play in this journey. Our commitment isn’t just to develop better transducers—it’s to ensure they serve a meaningful purpose in enhancing public safety, reducing environmental impact, and improving operational efficiency.

We work closely with rail operators, government agencies, and academic institutions to ensure our solutions are practical, sustainable, and future-ready.

Challenges and Considerations

Of course, no technology is without its challenges. The path forward for transducers in railway automation comes with its share of hurdles:

- Environmental conditions: Harsh climates, vibrations, and electromagnetic interference can affect transducer performance.

- Data security: With more connected devices, cybersecurity becomes crucial to prevent unauthorized access or system tampering.

- Interoperability: Ensuring that transducers from different vendors and legacy systems can work together smoothly is a key technical challenge.

- Cost vs. Benefit: Not every railway network has the budget to implement the latest technology. Finding scalable, affordable solutions is essential for widespread adoption.

GET IN TOUCH

In a hurry? Call us at 276-285-3841

Real-World Applications Already Underway

Many of these futuristic trends are already in motion. In Europe and parts of Asia, smart rail corridors equipped with wireless transducers are under development. These corridors can detect track conditions, train presence, and even maintenance needs in real-time.

In North America, some freight operators are using transducer-based systems to monitor wheel stress and axle temperatures, reducing derailments and saving millions in potential losses.

Swartz Engineering has contributed to several such pilot projects, supplying custom-engineered transducers tailored for rugged railway environments. The feedback we’ve received is encouraging and points to a future where transducers will be even more deeply embedded in the railway ecosystem.

A Vision of What’s Next

Looking ahead, we believe that the future of transducers in railway automation will be defined by three major pillars:

- Integration – Transducers will become seamlessly integrated with broader automation and AI platforms, providing real-time insights and predictive analytics.

- Adaptability – Systems will be designed to learn and adapt over time, thanks to machine learning models fed by transducer data.

- Sustainability – With climate concerns front and center, transducers will support greener railway systems by optimizing energy use and reducing resource waste.

Imagine a world where train delays are nearly eliminated, accidents are virtually nonexistent, and energy usage is finely tuned—all made possible by the humble yet powerful transducer.

Conclusion

The journey toward railway automation is as much about intelligent sensing as it is about high-speed trains and digital controls. Transducers in railway automation are not just passive components—they are the active sensors making smarter, safer railways a reality.

At Swartz Engineering, we’re excited to be at the forefront of this transformation. As we continue to innovate, collaborate, and refine our technology, we invite you to join us in shaping the future of railway automation—one transducer at a time.

Products We Offer

Swartz Engineering strives to provide top-quality products to achieve our customer's needs. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations

For nearly half a century, we have proudly led the industry in ensuring safety and efficiency. Swartz Engineering is a trusted family-owned company dedicated to providing top-notch power distribution solutions for the electrical industry. Contact us today!