Reliable rail operations depend on one critical foundation: a properly designed and executed railway power supply system. From early feasibility studies to final commissioning and long-term upgrades, every phase must be technically sound and tightly coordinated. In the USA, Swartz Engineering provides end-to-end railway electrical project support that helps rail operators, EPC contractors, and infrastructure owners deliver safe, compliant, and resilient power systems. Instead of fragmented services, clients get a continuous engineering thread across the full project lifecycle.

Rail stakeholders searching for dependable project outcomes usually want three things upfront: system reliability, regulatory compliance, and reduced lifecycle risk. End-to-end support addresses all three by aligning studies, design, procurement, installation, testing, and post-startup services under one technical framework.

Key Takeaways

- End-to-end railway power supply support reduces technical gaps between design and field execution

- Swartz Engineering provides lifecycle services across studies, design, testing, and upgrades in the USA

- Integrated engineering lowers change orders and commissioning delays

- Detailed system studies improve safety margins and future load readiness

- Continuous technical ownership supports long-term asset performance

Why End-to-End Support Matters in Railway Electrical Projects

Rail electrical infrastructure is not modular in practice, even if it looks modular on drawings. Substations, feeders, protection schemes, SCADA, and grounding grids are tightly interdependent.

A few realities seen repeatedly in U.S. rail projects:

- Small modeling errors can lead to large protection miscoordination

- Vendor equipment mismatches cause interface failures

- Field routing changes affect fault levels and grounding performance

- Incomplete studies lead to undersized capacity within a few years

End-to-end engineering support addresses these risks early and keeps assumptions consistent across phases.

Swartz Engineering works with:

- Passenger rail authorities

- Freight rail operators

- Transit agencies

- Rail EPC contractors

- Infrastructure developers

Their role is not limited to drawings. It includes analytical validation, field verification, and performance confirmation.

CONTACT US

Take the first step towards powering up your operations! call us at 276-285-3841

Early-Phase Studies and System Modeling

Strong projects start with strong analysis. One of the most important services in a railway power supply program is front-end electrical study work.

Typical early-stage services include:

- Load flow analysis across traction networks

- Short-circuit and fault duty calculations

- Harmonic and power quality studies

- Regenerative braking impact analysis

- Capacity forecasting for network expansion

- Utility interconnection assessments

These studies help answer practical planning questions:

- Will the traction substations handle peak headways?

- Are feeder cables sized for future rolling stock?

- Do protection devices have sufficient interrupting ratings?

- Will voltage drop affect train performance?

Swartz Engineering performs detailed simulation and scenario modeling so owners can make capital decisions based on data, not assumptions.

Detailed Engineering and Design Packages

Design quality directly affects construction speed and operational safety. Railway electrical systems must meet strict rail, utility, and safety codes across U.S. jurisdictions.

Swartz Engineering produces construction-ready packages that typically cover:

- Traction substation layouts

- AC and DC distribution design

- Protection and relay coordination schemes

- Grounding and bonding systems

- Negative return and stray current control

- Cable schedules and routing plans

- Control and SCADA integration diagrams

Design deliverables are structured for:

- Clear contractor interpretation

- Faster permitting review

- Reduced RFIs and change orders

- Easier inspection and approval

A consistent complaint from contractors is unclear design intent. A consistent strength noted by clients is when design documentation answers field questions before they are asked.

Equipment Specification and Vendor Review

Equipment selection in railway power supply projects is often underestimated. Technical compatibility matters more than unit price.

Specification support from Swartz Engineering includes:

- Transformer and rectifier sizing criteria

- Switchgear rating and duty requirements

- Protection relay feature requirements

- Environmental and enclosure standards

- Interface requirements with signaling and SCADA

- Spare parts and maintainability criteria

Vendor submittal review covers:

- Rating verification

- Protection logic alignment

- Interface compatibility

- Compliance with project standards

This process helps prevent a common failure mode: individually compliant components that fail as a system.

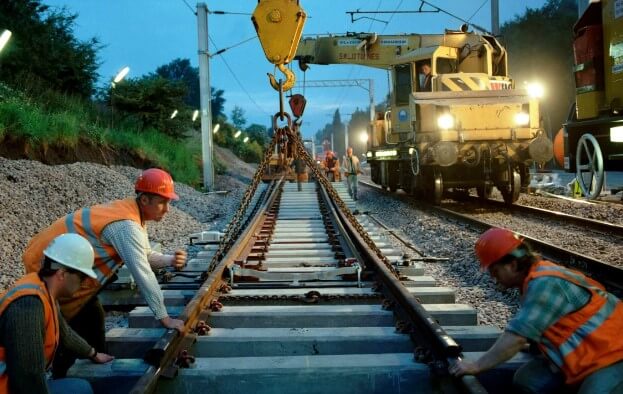

Construction and Field Engineering Support

Rail environments are rarely forgiving job sites. Work often occurs near live tracks, in tight substations, or within active corridors.

Field support services include:

- Installation review and validation

- Ground grid continuity checks

- Cable routing and segregation verification

- Protection panel inspections

- Settings validation for relays and breakers

- Field issue resolution with contractors

Swartz Engineering engineers coordinate directly with:

- Site supervisors

- Electrical contractors

- Utility representatives

- Safety officers

Quick technical decisions in the field prevent schedule drift and unsafe improvisation.

CONTACT US

Take the first step towards powering up your operations! call us at 276-285-3841

Testing and Commissioning Services

Commissioning is where theoretical performance meets operating reality. A structured test program is essential for railway power supply acceptance.

Typical commissioning support includes:

- Factory acceptance test (FAT) participation

- Site acceptance testing (SAT)

- Relay testing and coordination confirmation

- Functional SCADA checks

- Energization procedures and checklists

- Fault simulation tests were permitted

Benefits of structured commissioning:

- Early defect detection

- Verified protection operation

- Reduced startup incidents

- Documented compliance record

Rail operators value commissioning partners who treat energization as a controlled engineering event, not a routine switch-on.

Monitoring, Diagnostics, and Modernization

Many U.S. rail systems are expanding or upgrading legacy infrastructure. Modern railway power supply systems increasingly include digital monitoring and predictive diagnostics.

Support areas include:

- Substation monitoring architecture

- Feeder load analytics

- Fault event recording systems

- Remote condition monitoring

- Predictive maintenance data models

Operational benefits:

- Faster fault location

- Trend-based maintenance scheduling

- Better expansion planning

- Reduced unplanned outages

Swartz Engineering supports both new installations and retrofit modernization programs.

Long-Term Support and System Upgrades

Rail systems are long-life assets. Loads increase. Standards evolve. Equipment ages.

Post-commissioning services often include:

- System audits

- Capacity reassessment studies

- Protection upgrades

- Retrofit design packages

- Expansion planning studies

- Compliance gap reviews

Keeping the original engineering partner involved preserves technical continuity and shortens troubleshooting cycles.

From an owner’s perspective, this reduces lifecycle uncertainty and protects capital investment.

Choosing the Right Railway Power Supply Partner

End-to-end railway power supply project support is not just a convenience — it is a risk control strategy. When studies, design, specifications, field support, and commissioning are technically aligned, projects run more smoothly, and systems perform better.

Swartz Engineering supports railway and transit clients across the USA with:

- Lifecycle electrical engineering

- Rail-specific analytical expertise

- Field-proven commissioning methods

- Standards-aligned design packages

- Long-term technical partnership

If you are planning, upgrading, or validating a railway power supply system, working with a dedicated engineering partner helps reduce surprises and improve operational reliability. Contact Swartz Engineering to review your project scope and get expert technical support tailored to your rail infrastructure needs.

Frequently Asked Questions

What is included in the railway power supply project support?

It typically includes system studies, detailed design, equipment specification, construction support, testing, commissioning, and upgrade planning.

Why are electrical studies important before rail construction?

They verify capacity, fault levels, and voltage performance so infrastructure is sized correctly and safely before installation.

How does end-to-end engineering reduce project risk?

It keeps assumptions and design intent consistent across all phases, reducing mismatches and field corrections.

Can existing rail substations be upgraded instead of replaced?

Yes. With proper audits and studies, many substations can be retrofitted with new protection, controls, and higher-capacity equipment.

Does Swartz Engineering work only on new rail projects?

No. They support new builds, expansions, retrofits, system audits, and modernization programs across U.S. rail networks.

Our Expert Services

Swartz Engineering provides top-quality products to achieve our customers' needs. We also make sure our products work reliably and safely. Our products include:

- Type 76 DC Relay

- Type 82 DC Relay

- Swartz Engineering’s Type 64 Ground Relay

- Type 32 Reverse Current Relay

- Type 150 DC

- CSM Shield Monitor

- Metal Oxide Surge Arrestors

- Transducers

- MVIS SL Slim-line Contactor

- Fully-tested Power Control Rooms

- Swartz Engineering’s Portable Substations

Contact Us

If you have a need for regular mobile power solutions, backups, or temporary power solutions, Swartz Engineering can deliver the crucial systems in a custom build for your needs. Contact us today to learn more about our mobile substation designs.

CONTACT US

Take the first step towards powering up your operations! call us at 276-285-3841