In today’s highly electrified world, monitoring and controlling electrical currents is crucial for safety, efficiency, and performance. Whether it’s in a power station, industrial plant, or renewable energy installation, accurate current measurement is the backbone of effective electrical system management. One of the most reliable devices used for this purpose is the current transducer—a technology that has evolved alongside modern engineering needs.

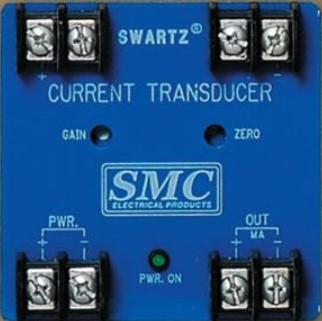

At Swartz Engineering, we design and supply advanced current transducers that combine precision, durability, and adaptability. But before we get into how these devices are used in real-world applications, let’s break down the current transducers' working principles, the types available, and where they fit into modern electrical systems.

Understanding the Basics: What is a Current Transducer?

A current transducer is an electrical device that converts current—whether alternating (AC) or direct (DC)—into a proportional output signal, usually a standard voltage or current signal, for measurement, monitoring, or control purposes.

In simple terms, a current transducer acts as the “translator” between a high-power circuit and low-power measurement or control equipment. It ensures that sensitive electronics can accurately read current values without being directly exposed to high voltages or hazardous conditions.

The Principles Behind Current Transducers Working

Current Transducers Working relies on fundamental electrical and magnetic principles, particularly electromagnetic induction or the Hall effect, depending on the type.

Here’s a simplified look at how they operate:

- Detection of Current Flow

When electrical current passes through a conductor, it generates a magnetic field proportional to the current’s magnitude.

- Conversion to a Measurable Signal

The transducer senses this magnetic field (using coils, sensors, or Hall effect devices) and converts it into a proportional voltage or current signal.

- Signal Conditioning

The raw signal is processed and standardized—often to a 4–20 mA or 0–5 V output—so it can be safely fed into data acquisition systems, controllers, or display instruments.

- Isolation for Safety

Most current transducers provide electrical isolation between the high-power and low-power sides, preventing dangerous voltages from reaching sensitive devices.

This combination of detection, conversion, conditioning, and isolation allows engineers to monitor electrical systems accurately and safely.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Types of Current Transducers

There’s no one-size-fits-all approach—different types of current transducers are suited to different environments and measurement needs. Let’s explore the most common ones:

1. AC Current Transducers

These are designed to measure alternating current. They often use current transformers (CTs) or Rogowski coils to detect magnetic fields produced by AC flow.

- Ideal for: Power distribution monitoring, AC motor control, and grid applications.

- Example: Swartz Engineering AC transducers for utility-grade accuracy.

2. DC Current Transducers

DC current doesn’t produce a changing magnetic field, so Hall effect sensors are typically used. These sensors detect the constant magnetic field produced by steady DC currents.

- Ideal for: Battery systems, solar power installations, and electric vehicle charging stations.

3. AC/DC Current Transducers

Hybrid designs that can measure both AC and DC currents accurately, offering flexibility in mixed-signal environments.

- Ideal for: Industrial automation systems, renewable energy plants, and variable frequency drive (VFD) monitoring.

4. Rogowski Coil-Based Transducers

These are flexible, lightweight coils used for measuring AC currents in large conductors or busbars where traditional CTs can’t fit.

- Ideal for: Temporary monitoring, large-scale industrial applications, and retrofit installations.

Key Advantages of Using Current Transducers

Current transducers offer several benefits that make them indispensable in modern electrical systems:

- Safety: Isolation ensures operators and equipment are protected from high voltages.

- Accuracy: High-precision designs allow for reliable measurement and control.

- Versatility: Available in various ranges and configurations for different applications.

- Compatibility: Standardized outputs integrate seamlessly with PLCs, SCADA systems, and digital meters.

- Durability: Industrial-grade designs, like those from Swartz Engineering, withstand harsh environments.

Applications of Current Transducers

Now that we’ve explored current transducers' working principles and types, let’s look at where they’re used in the real world.

1. Power Generation and Distribution

In power plants and substations, current transducers monitor load currents, detect faults, and help ensure balanced system operation. This data is essential for avoiding overloads and blackouts.

2. Industrial Automation

Manufacturing facilities use current transducers to monitor motors, detect phase imbalances, and manage energy consumption, improving productivity and reducing downtime.

3. Renewable Energy Systems

In solar farms, wind turbines, and battery storage facilities, transducers measure both AC and DC currents to maximize energy conversion efficiency.

4. Electric Vehicle (EV) Infrastructure

Charging stations rely on DC current transducers for accurate billing, safety monitoring, and load management.

5. Marine and Aerospace

Specialized current transducers are used in ships and aircraft to ensure reliable operation of electrical systems in demanding environments.

GET IN TOUCH

The ultimate solution for reliable power control! call us at 276-285-3841

Why Choose Swartz Engineering for Current Transducers?

At Swartz Engineering, we’ve been perfecting the art and science of current measurement for decades. Our transducers are:

- Precision-engineered for optimal accuracy.

- Built for longevity, even in extreme operating conditions.

- Customizable to meet specialized application needs.

- Tested rigorously to meet industry standards for performance and safety.

We don’t just sell products—we provide solutions. Our engineering team works closely with clients to match them with the perfect transducer for their operational requirements.

Future of Current Transducers

The next generation of current transducers will integrate smart features like digital communication interfaces, self-calibration, and predictive diagnostics. As energy systems become more interconnected and data-driven, these intelligent transducers will play a central role in grid stability, energy efficiency, and equipment longevity.

Swartz Engineering is already exploring innovations in this area, combining our proven hardware expertise with cutting-edge digital capabilities.

Conclusion

Understanding how current transducers work is more than just knowing the electrical theory—it’s about recognizing their role in keeping our energy systems safe, efficient, and sustainable. From industrial automation to renewable energy, these devices quietly but powerfully ensure that current is measured, monitored, and managed with precision.

As electrical networks become more complex, the demand for accurate, reliable current measurement will only grow. With Swartz Engineering’s commitment to quality and innovation, we’re ready to meet that demand—today and in the future.

Explore The Best Current Transducer Solution For Your Project

Contact Swartz Engineering today and let our experts guide you toward the perfect fit for your application.